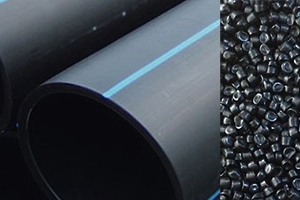

The use of compound granules in high-pressure gas pipes offers several significant advantages:

- Enhanced Strength and Durability: Compound granules, often reinforced with fibers like glass or carbon, improve the mechanical strength of the pipes, enabling them to withstand high internal pressures without failure or deformation. This makes them ideal for high-pressure gas transportation, where structural integrity is crucial.

- Chemical Resistance: The compound granules are engineered to resist the harsh chemicals commonly found in natural gas, such as hydrogen sulfide (H2S).This ensures the longevity of the pipes and prevents degradation from exposure to corrosive substances.

- Low Gas Permeability: The granules contribute to a low permeability of the pipes, reducing the risk of gas leakage. This is particularly important in gas pipelines where preventing leaks is essential for safety and efficiency.

- Fire Resistance: Many compound granules include additives that enhance fire resistance, helping to prevent ignition or the spread of flames in the event of a leak.This property is crucial for safety in gas transport, especially in urban or industrial areas.

- Impact Resistance: The incorporation of reinforcements and stabilizers in compound granules provides the pipes with high impact resistance, making them less prone to damage during installation, handling, or external stresses.

- Customization: The formulation of compound granules can be adjusted to meet specific requirements, such as resistance to particular chemicals, temperature fluctuations, or pressure conditions. This flexibility allows manufacturers to create pipes that are perfectly suited to their application.

- Cost-Effectiveness: By using compound granules, manufacturers can produce high-performance pipes more efficiently and at a lower cost compared to alternative materials, making them a cost-effective solution for gas transportation systems.

These advantages make compound granules a critical material for the production of safe, durable, and reliable high-pressure gas pipes.

In summary, compound granules used in the manufacture of high-pressure and gas pipes are carefully formulated to offer superior strength, durability, resistance to corrosion, and other critical properties. These granules play a vital role in ensuring the safe, efficient, and long-lasting performance of pipes in demanding environments.

AMTOP.CO

Amtop is a company that specializes in manufacturing advanced materials, including compound granules, which are commonly used in the production of high-pressure and gas pipes. These compound granules are essential in ensuring that pipes can handle the demanding conditions of high-pressure systems and gas transportation.