A compound granule for pipe production is a mixture of different materials, including polymers, additives, and sometimes recycled plastics, that are processed into small pellets.These pellets are then melted and extruded or molded to create pipes with specific properties and applications.

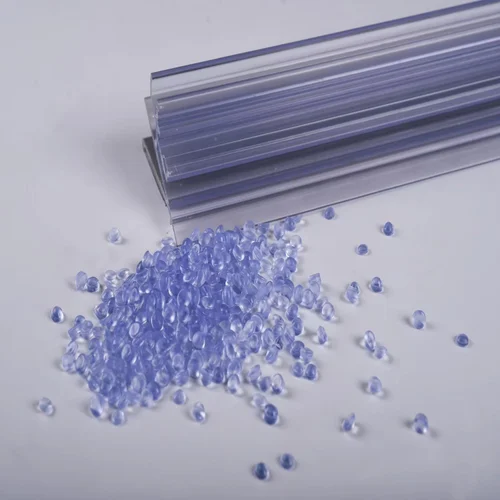

compound for transparent pipe

pvc compound granules for pipe

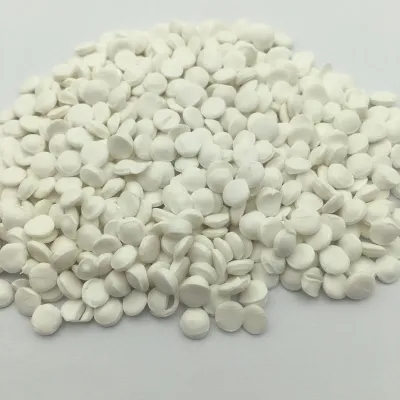

polypropylene

CPVC (Chlorinated Polyvinyl Chloride) Compound Granules

The specific composition of a compound granule will depend on the desired properties of the final pipe product, such as strength, flexibility, chemical resistance, and temperature resistance.

The future of compound granules for pipe manufacturing is poised for significant advancements driven by technological innovations and a growing emphasis on sustainability. As recycling technologies continue to improve,more efficient and higher-quality recycled plastics will be integrated into compound granules,reducing the reliance on virgin materials and further promoting a circular economy. The development of new additives will enhance the performance of pipes, providing greater resistance to environmental factors such as UV radiation,chemicals, and extreme temperatures.

Additionally, there is a rising trend toward incorporating smart technologies, such as sensors embedded within pipes, to monitor critical factors like pressure and flow. These innovations will lead to the production of more durable, efficient, and eco-friendly pipes, meeting the increasing demand for sustainable construction and industrial solutions.

AMTOP is a leading manufacturer of high-quality compound granules for pipe production, offering a wide range of products tailored to various applications, including PVC, PE, PP, and CPVC compounds.

©AmTop. All Rights Reserved