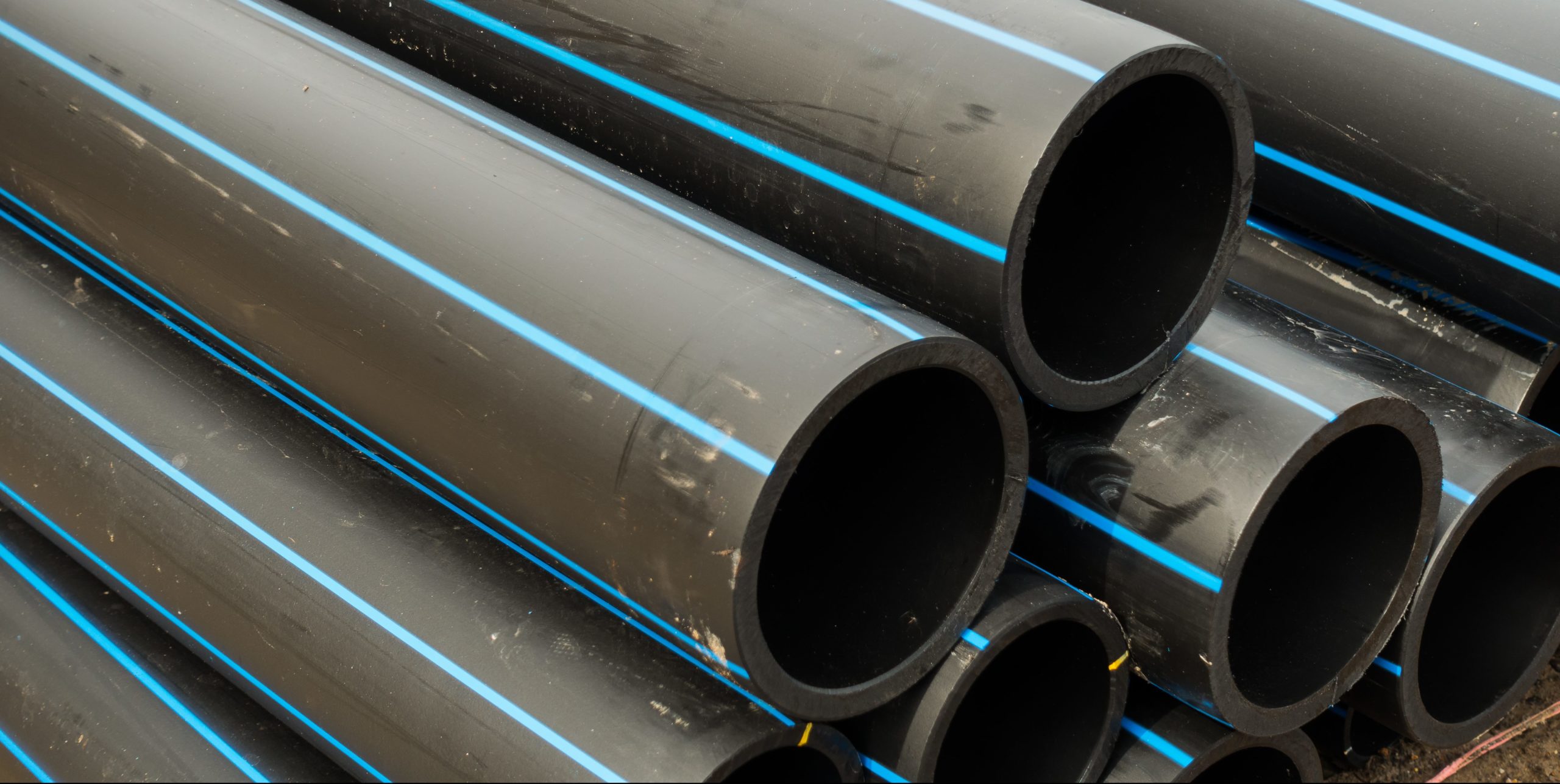

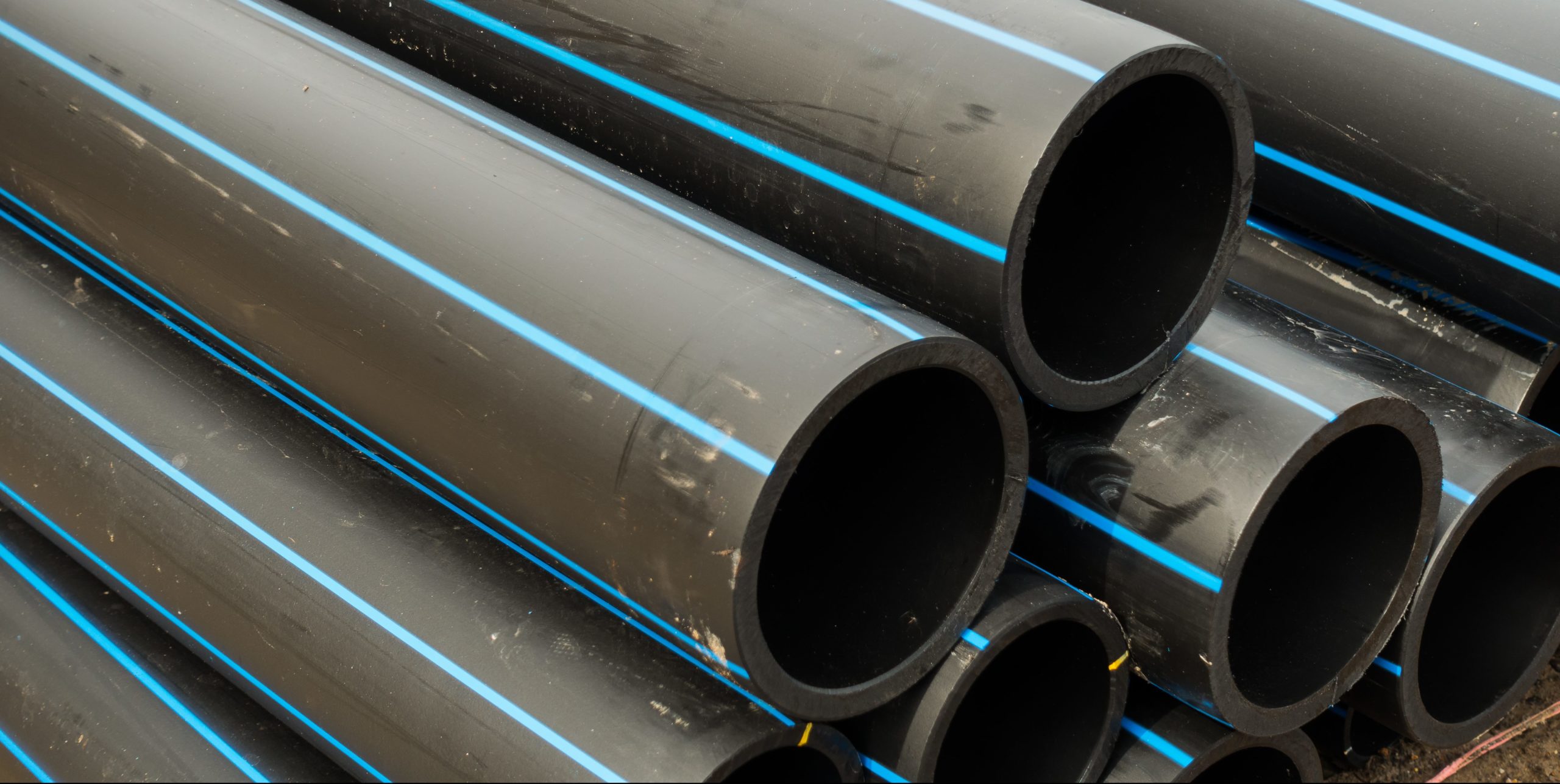

HDPE PIPE FITTING are widely used in various industries due to their exceptional durability, flexibility, and chemical resistance. These fittings are specifically designed to connect, join, or terminate HDPE pipes in water supply, gas distribution, industrial applications, and more.

Key Features of HDPE Pipe Fittings

- Material Strength: HDPE pipe fittings have excellent tensile strength and impact resistance.

- Chemical Resistance: Resistant to acids, bases, salts, and most chemicals, making them suitable for industrial applications.

- Corrosion Resistance: Unlike metal fittings, HDPE does not corrode or rust.

- Flexibility: The material can absorb vibrations and stress, making it suitable for areas prone to seismic activities or ground movement.

- Lightweight: Easy to transport and install compared to metal alternatives.

- Leak-Free Connections: When fused, the joints form a single, seamless system.

Types of HDPE Pipe Fittings

HDPE pipe fittings come in various types to meet different connection and application needs:

1. Butt Fusion Fittings

- Description: Joined by heating the ends of the pipes and fittings and pressing them together.

- Common Types:

- Elbows (45°, 90°)

- Tees (equal and reducing)

- Reducers

- Caps

- Applications: Water pipelines, gas distribution systems, industrial piping.

2. Electrofusion Fittings

- Description: Equipped with built-in heating elements that are activated to melt the pipe surface for a secure connection.

- Common Types:

- Couplers

- Branch Saddles

- Tapping Saddles

- Applications: Gas pipelines, water supply systems, and systems requiring high integrity joints.

3. Compression Fittings

- Description: Require no welding; connect pipes mechanically using compression rings and nuts.

- Common Types:

- Couplings

- Adapters (male and female threaded)

- End caps

- Applications: Temporary or portable systems, irrigation, and low-pressure systems.

4. Flange Fittings

- Description: Used to connect HDPE pipes to valves, pumps, or other piping materials via bolted connections.

- Common Types:

- Flange Adapters

- Backing Rings

- Applications: Industrial systems, water treatment plants.

5. Socket Fusion Fittings

- Description: Pipes and fittings are heated separately and then joined together.

- Common Types:

- Applications: Smaller diameter pipes, plumbing systems.

6. Custom Molded Fittings

- Description: Specially designed for unique project requirements.

- Applications: Complex pipeline networks, mining, and chemical transport.

Advantages of HDPE Pipe Fittings

- Durability: Withstand heavy loads, impacts, and harsh environmental conditions.

- Longevity: Can last 50+ years in most applications.

- Low Maintenance: Require minimal upkeep due to their resistance to scaling, corrosion, and abrasion.

- Flexibility: Accommodate ground movement, reducing the risk of breaks or leaks.

- Environmentally Friendly: Fully recyclable and reduce water loss due to leak-free joints.

- Cost-Effective: Lower transportation, installation, and maintenance costs compared to traditional materials.

Applications of HDPE Pipe Fittings

- Water Supply:

- Potable water pipelines

- Irrigation systems

- Gas Distribution:

- Underground gas piping systems

- Industrial Piping:

- Transport of chemicals, slurries, and waste.

- Sewage and Drainage:

- Wastewater systems

- Stormwater drainage

- Mining:

- Transport of slurry and corrosive materials.

- Telecommunications:

- Protection of fiber-optic and electrical cables.

Installation Techniques

1. Butt Fusion

- Requires specialized equipment to heat and press pipe ends together.

- Forms a strong, seamless joint.

2. Electrofusion

- Uses fittings with built-in heating coils.

- Offers reliable connections for high-pressure applications.

3. Mechanical Joining

- No welding required; uses compression or flanges.

- Ideal for temporary or portable systems.

Standards and Specifications

HDPE pipe fittings are manufactured to meet industry standards, including:

- ISO 4427: For water supply applications.

- ASTM D3035: For pressure piping systems.

- EN 12201: For water and sewage systems.

- PE 80/PE 100 Grades: Define the material’s strength and pressure rating.

Maintenance and Troubleshooting

- Regularly inspect for leaks or blockages.

- Ensure proper handling and installation to avoid stress damage.

- Clean fittings to prevent contamination in water systems.

Conclusion

HDPE pipe fittings provide a reliable and versatile solution for various piping needs. Their durability, leak-proof connections, and resistance to harsh conditions make them a preferred choice in water, gas, industrial, and sewage applications. With proper selection and installation techniques, HDPE pipe fittings can offer decades of maintenance-free performance.