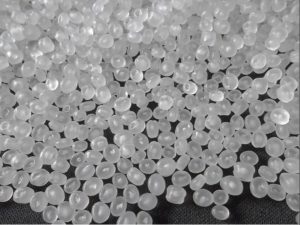

hdpe granule for blow molding

hdpe granule for blow molding are a form of High-Density Polyethylene (HDPE) specifically designed for use in the blow molding process. These granules are small, pellet-like raw materials used to create a variety of plastic products through the blow molding technique, which involves forming hollow shapes by inflating heated plastic.

Key Features of hdpe granule for blow molding :

- High Strength and Durability: HDPE granules are known for their excellent mechanical properties, including high tensile strength, impact resistance, and durability, making them suitable for creating strong and long-lasting products.

- Lightweight: Despite its strength, HDPE is a lightweight material, making it ideal for applications where weight is a concern, such as in packaging materials like bottles and containers.

- Chemical Resistance: HDPE offers resistance to a wide range of chemicals, acids, and solvents, making it a preferred choice for packaging chemical products, including detergents, cleaning agents, and industrial fluids.

- Excellent Processability: HDPE granules melt uniformly and exhibit good flow properties during blow molding, ensuring a smooth and consistent production process with minimal defects.

- Recyclability: HDPE is highly recyclable, making it a more environmentally friendly option compared to other plastics. Recycled HDPE can be used in a variety of products, helping reduce waste.

Applications of HDPE Granules in Blow Molding:

HDPE granules for blow molding are used to manufacture a wide range of products, including:

- Bottles and containers: Common for packaging liquids like water, milk, oils, shampoos, and household cleaning products.

- Drums and barrels: For industrial and chemical storage.

- Toys: Many hollow plastic toys are made using HDPE due to its lightweight and non-toxic nature.

- Fuel tanks: HDPE is used in automotive industries for creating lightweight and durable fuel tanks.

- Water tanks and other hollow storage containers: For residential or industrial purposes.

Types of Blow Molding Using HDPE Granules:

- Extrusion Blow Molding (EBM): HDPE granules are melted and extruded into a tube-like parison, which is then inflated inside a mold to take the desired shape.

- Injection Blow Molding (IBM): This method involves injecting molten HDPE into a mold to form a preform, which is then blown into its final shape.

- Stretch Blow Molding (SBM): Mainly used for creating bottles and containers, where the preform is stretched and inflated simultaneously to produce a more uniform and strong final product.

Grades of HDPE Granules for Blow Molding:

- Standard HDPE Grades: For general-purpose applications like making bottles and containers.

- High Molecular Weight HDPE (HMW-HDPE): For more demanding applications requiring greater strength and impact resistance, such as large drums and industrial containers.