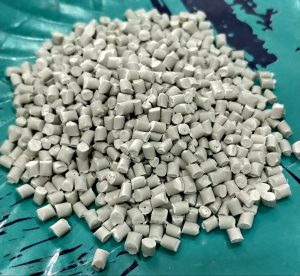

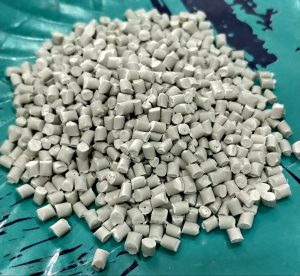

Granules for raffia

Granules for raffia , primarily made from polypropylene (PP), are a type of thermoplastic polymer used extensively in the production of raffia yarns, tapes, and products. They are an integral part of industries focused on packaging, agriculture, and construction, given their lightweight, durability, and cost-efficiency.

Composition and Additives

Raffia granules are more than just raw polypropylene. They often include additives to enhance performance for specific applications:

Base Material:

- Polypropylene (PP):

- Known for its strength, flexibility, and resistance to fatigue, polypropylene is ideal for manufacturing products that require durability and long-term use.

Key Additives:

- UV Stabilizers:

- Protect the final raffia products from prolonged UV exposure, preventing discoloration and brittleness.

- Essential for outdoor applications like agricultural twines and sacks.

- Color Masterbatch:

- Granules can be mixed with color masterbatches to produce colored raffia products.

- Common colors include white, black, green, and custom shades for branding.

- Anti-Oxidants:

- Prevent oxidation during the high-temperature processing of granules, enhancing the product’s lifespan.

- Slip and Anti-Slip Agents:

- Modify surface properties to improve handling.

- Slip agents make the raffia smoother for applications requiring easy sliding or feeding through machines.

- Anti-slip agents add friction, critical for applications like stacking woven bags.

- Calcium Carbonate (Filler):

- Added in specific formulations to reduce cost and improve certain mechanical properties.

Characteristics of Raffia Granules

Raffia granules are specifically designed to meet the needs of manufacturers and end-users, offering the following properties:

Physical Properties:

- High tensile strength, allowing the final products to withstand heavy loads.

- Lightweight, ensuring cost-effective transportation and handling.

- Low moisture absorption, making them ideal for outdoor and agricultural use.

Chemical Resistance:

- Resistant to chemicals, oils, and organic solvents, ensuring durability in harsh environments.

Thermal Properties:

- High melting point (approximately 160–170°C for PP), suitable for extrusion and stretching processes.

Types of Raffia Granules

Raffia granules can be classified based on their source and quality:

Virgin Raffia Granules:

- Made from pure, newly polymerized polypropylene.

- Consistent quality, high strength, and reliability.

- Primarily used for premium-grade raffia products like woven sacks for food-grade applications.

Recycled Raffia Granules:

- Manufactured from reprocessed polypropylene waste.

- Eco-friendly and cost-effective but may have slightly lower mechanical properties.

- Used for non-critical applications like construction tarps or secondary packaging.

Blended Raffia Granules:

- A combination of virgin and recycled granules.

- Strikes a balance between cost and performance.

Manufacturing Process Using Raffia Granules

The transformation of raffia granules into finished products involves several steps:

1. Extrusion:

- Granules are fed into an extruder, where they are melted and formed into thin, flat tapes.

2. Stretching:

- Tapes are stretched longitudinally to improve their tensile strength and flexibility.

- This step is critical for creating strong, durable raffia yarns.

3. Winding:

- The stretched tapes are wound onto bobbins for storage or direct use in weaving machines.

4. Weaving:

- Tapes are woven into fabrics, which can be further processed into products like bags, sacks, or mats.

5. Lamination (Optional):

- A thin film of PP or PE is laminated onto the woven fabric to make it waterproof and suitable for applications like fertilizer or grain storage.

Applications of Raffia Granules

Raffia granule are versatile and find use in a wide range of products across industries:

Packaging Industry:

- Woven Sacks:

- Bags for storing grains, sugar, rice, cement, and fertilizers.

- FIBC Bags (Flexible Intermediate Bulk Containers):

- Large-scale sacks used for transporting bulk goods.

Agriculture:

- Twines and Ropes:

- Used for tying and bundling crops or hay.

- Ground Covers and Geotextiles:

- Prevent weed growth and improve soil stabilization.

Construction:

- Construction Sheets:

- Used as covers for scaffolding or temporary shelters.

Home and Decorative Items:

- Mats and Carpets:

- Durable and lightweight mats for homes or outdoor use.

- Handicrafts:

- Colored raffia yarns are used in basket weaving and other crafts.

Benefits of Raffia Granules

- Cost-Effective Production:

- The lightweight nature of polypropylene reduces raw material costs while maintaining high strength.

- Customizability:

- Granules can be tailored with additives and colors to suit specific applications.

- Environmentally Friendly Options:

- Recycled granules promote sustainability and reduce waste.

- High Durability:

- UV and chemical resistance ensure the longevity of raffia products.

Challenges in Using Raffia Granules

While raffia granule are highly versatile, there are certain challenges:

- Environmental Impact:

- Virgin polypropylene granules are non-biodegradable. However, efforts to increase recycling and develop biodegradable alternatives are ongoing.

- Processing Sensitivity:

- Precise control over extrusion and stretching is required to achieve consistent product quality.

Advancements in Raffia Granules Technology

Modern innovations are focusing on:

- Bio-Based Polymers:

- Developing raffia granule from plant-based materials for reduced environmental impact.

- Enhanced UV Stabilizers:

- Improving the lifespan of outdoor raffia products.

- High-Speed Processing:

- Advancements in machinery for faster and more efficient production.

Conclusion

Raffia granule are a cornerstone of modern industrial and agricultural applications, offering a cost-effective, durable, and versatile solution for a variety of needs. Their ability to be tailored with additives and recycled content makes them a valuable resource for both traditional manufacturing and sustainable innovation.