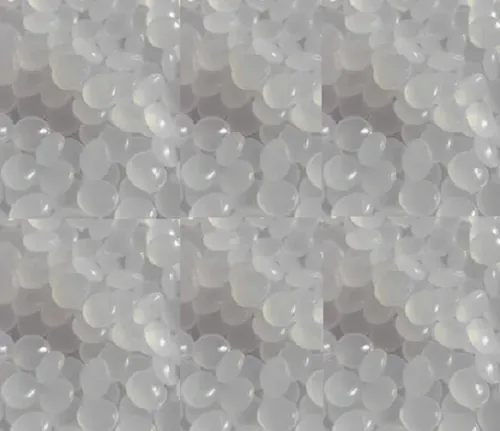

LLDPE granule for blow molding film

LLDPE (Linear Low-Density Polyethylene) granules are widely used in blow molding applications for producing films due to their beneficial properties. Here are some details about LLDPE granules specifically designed for blow molding film production:

Key Features of LLDPE for Blow Molding Film

- High Strength: LLDPE offers excellent tensile strength, making the resulting film tough and durable while allowing it to withstand impact and stretching.

- Flexibility and Elasticity: Films made with LLDPE are more flexible compared to HDPE films, which allows for greater resistance to punctures and tears.

- Transparency: LLDPE films typically have good clarity and gloss, making them ideal for packaging applications where visibility is important.

- Good Heat Sealing Properties: LLDPE has a relatively low melting point, enabling effective sealing at lower temperatures, which is ideal for high-speed packaging operations.

- Compatibility with Additives: LLDPE granules can be mixed with various additives like UV stabilizers, anti-block agents, and slip agents to enhance film properties according to specific requirements.

Common Applications

LLDPE granules for blow molding are primarily used in:

- Packaging Films: Used for food packaging, agricultural films, stretch wraps, and liners.

- Industrial Films: Covers for goods in storage or transport.

- Agricultural Films: For greenhouse covers, silage films, and mulch films due to their flexibility and durability.

Grades and Selection

LLDPE granules for blow molding are available in different grades, with each grade tailored for specific properties like:

- Thickness requirements: Thinner films require granules with specific flow characteristics.

- Optical properties: Certain grades are chosen to achieve greater transparency and gloss.

- Processing requirements: Grades vary based on compatibility with different blow molding machinery.

Processing of LLDPE granule for blow molding film

The blow molding process for LLDPE typically includes the following steps:

- Extrusion: LLDPE granules are melted and extruded through a die, forming a tubular shape.

- Blowing: The tube is inflated with air, stretching it to form a thin, even film.

- Cooling: The inflated film is cooled and then wound onto rolls for further processing or distribution.

When choosing LLDPE granules for blow molding film, manufacturers often work with suppliers to select the right grade and blend to meet their specific needs, including factors like tear strength, puncture resistance, and flexibility.

typs of grade LLDPE granule for blow molding film

219NJ:The LLDPE grade 219NJ is a specific type of Linear Low-Density Polyethylene commonly used in applications like blown film extrusion due to its unique properties.

220HT:The LLDPE grade 220HT is another specific Linear Low-Density Polyethylene variant often used for blown film extrusion applications. This grade is designed to provide a balance of strength, flexibility, and processing efficiency.

220WT:The LLDPE grade 220WT is a Linear Low-Density Polyethylene that is optimized for blown film applications, particularly where strength, clarity, and toughness are key requirements.

222WF:LLDPE grade 222WF is a Linear Low-Density Polyethylene specifically engineered for blown film applications, commonly used in packaging due to its favorable combination of strength, flexibility, and processability.

222WT:LLDPE grade 222WT is a Linear Low-Density Polyethylene grade tailored for blown film extrusion applications. It is widely used in packaging due to its excellent balance of strength, flexibility, and optical properties.

318BJ:LLDPE grade 318BJ is a specialized Linear Low-Density Polyethylene grade designed for blown film applications. It is often selected for applications where strength, flexibility, and film clarity are important.

318CNJ:LLDPE grade 318CNJ is a Linear Low-Density Polyethylene specifically developed for blown film applications where a combination of strength, clarity, and flexibility is required. This grade is particularly popular in the packaging industry for making films that need durability along with good optical properties.

320BJ:LLDPE grade 320BJ is a Linear Low-Density Polyethylene used primarily in blown film applications. It is particularly valued for its strength, flexibility, and ease of processing. This grade is suitable for creating durable films with a balance of mechanical properties that make it versatile for various industrial and packaging uses.

320NT:LLDPE grade 320NT is a Linear Low-Density Polyethylene grade specifically designed for blown film extrusion applications. Known for its high strength, flexibility, and clarity, this grade is often used in packaging that demands durability along with good optical qualities.

324CNJ:LLDPE grade 324CNJ is a specialized Linear Low-Density Polyethylene grade, optimized for blown film extrusion applications. It is commonly selected in packaging applications that demand a combination of durability, flexibility, and clarity. This grade is popular for producing high-strength films suitable for both consumer and industrial uses.

518NT:LLDPE grade 518NT is a Linear Low-Density Polyethylene specifically engineered for blown film applications and is recognized for its high clarity, durability, and flexibility. This grade is commonly used in film products where transparency and resilience are essential, such as packaging films that need to display contents while being durable enough for handling and transport.

6118NSF:LLDPE grade 6118NSF is a Linear Low-Density Polyethylene grade tailored for blown film applications that require high levels of strength, flexibility, and compliance with food safety standards. The NSF designation typically indicates that the material is certified for applications that involve food contact, making it ideal for packaging within the food industry.

6318BJ:LLDPE grade 6318BJ is a Linear Low-Density Polyethylene grade engineered for blown film applications where high strength, flexibility, and durability are essential. This grade is well-suited for films used in both industrial and consumer packaging, especially where toughness and impact resistance are critical.

6821NE:LLDPE grade 6821NE is a Linear Low-Density Polyethylene resin developed specifically for blown film extrusion applications. It is known for its strong mechanical properties, flexibility, and ease of processing, making it a popular choice in various packaging industries.